Chlorination has been the principal selection of most wastewater disinfection operations since the early 1900’s. Although chlorination is still used in the majority of disinfection applications, alternative processes are increasingly being selected. Ultraviolet (UV) irradiation has become the most common alternative to chlorination for wastewater disinfection in North America.

So what is Ultraviolet light? Ultraviolet light is a form of radiation which is not visible to the human eye. Ultraviolet rays have shorter wavelengths than visible light. A wavelength, the distance between the crest of two waves, is often measured in units called nanometers. A nanometer (nm) is a billionth of a meter or about 1/25,000,000 inch.

Ultraviolet rays with wavelengths shorter than 300 nm are extremely effective in killing bacteria and viruses. The most effective sterilizing range for UV is within the C bandwidth (UVC). This range is referred to as the germicidal bandwidth and measures from 100-280nm. UV radiation in wavelengths of 253.7 nm is capable of destroying virtually all known forms of microorganisms and viruses.

How does UV disinfection work? When microbes such as bacteria, bacterial spores, viruses, yeast, mold and mold spores are exposed to sufficient doses of UVC light, their DNA is destroyed causing cell death and making cell division impossible. UV rays must strike the contaminants directly in order to penetrate the microorganisms and break down its molecular bonds. This bond breakage translates into cellular or genetic damage with the germs rendered harmless by robbing them of the ability to reproduce. Since UVS leaves no product residues or contaminants, it is an environmentally friendly alternative to using chemicals.

The Enviro-Flo UV disinfection unit, model Salcor 3G, is specifically designed for disinfecting the effluent from small aerobic treatment systems. It is manufactured by Salcor Inc, one of the leaders in UV technology. The unit is capable of reducing coliform bacteria well below the most stringent US treatment standards. Testing was performed to internationally recognized performance standards and was capable of reducing fecal coliforms to a level averaging <70 cfu/100ml.

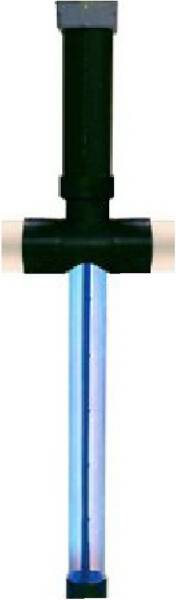

The Enviro-Flo UV disinfection chamber is constructed from carbon impregnated ABS plastic and is coupled to the aerobic plant discharge pipe and is permanently installed below grade. The ultraviolet light source for disinfection is mounted in a sub-assembly that can be inserted or removed through the top of the riser pipe for periodic servicing. The light source is mounted in the center of an anodized aluminum frame that divides the disinfection chamber in half. The frame seals against the inner surface of the disinfection chamber to prevent flow by pass. The ultraviolet light source is surrounded by a clear fused quartz tube to control lamp surface temperature. A clear Teflon® film covers the quartz tube to minimize surface fouling.

When fully inserted, the disinfection sub-assembly is properly located by pins mounted near the top of the disinfection chamber. This design causes the wastewater to enter one side of the unit and flow vertically downward. The wastewater takes an 180˚ turn and flows vertically upward and out the other side of the unit. This well defined flow path is designed to give the proper fluid exposure time. When the disinfection chamber is filled with water, the ultraviolet light source can operate continuously. Continuous operation within a lamp surface temperature range of 105˚-120˚ F provides optimum ultraviolet light output and long lamp life.

Operating status of the disinfection system is confirmed by conveying a visible light from the ultraviolet light source located underground to an electrical junction box mounted on the outside surface of the riser pipe by a fiber optic probe. This allows for lamp operating status to be confirmed visually without the necessity for removing the disinfection sub-assembly.

The disinfection sub-assembly is watertight throughout its length, which extends approximately one foot above grade which in turn protects the electrical connections against a fluid backup which could cause the wastewater effluent level to rise to the maximum height of the treatment plant.

The Salcor 3G was designed by Dr. James Cruver, president of Salcor Engineering, Inc. Dr. Cruver is the author of over 40 scientific papers and a textbook on UV treatment. Models are available for up to 10 million gal/day.